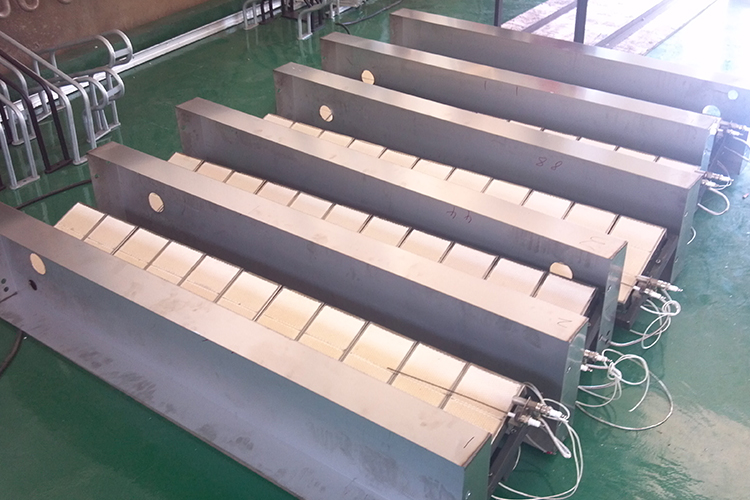

Product Description

Model NO.: K1100 Structure Material: Metal Material Mixing Heat Exchanger Type: Jetheat Exchanger Certification: CE Specification: CE HS Code: 8416201190 Principle: Mixing Heat Exchanger Application: Heater Heat Transfer Surface: Plate Heat Exchanger Trademark: SUNSRAYS Origin: Shenzhen, China The K Series Integrated Mesh Group Infrared Burners are Sunsrays' patent products. They are designed and produced for multi-purposes, such as powder coating, drying, food process, latex dipping industries, etc.

The K series burners can be applied with an air/gas pre-mixer or a normal nozzle. It means that the burners can be used either with naturally pre-mixed air and gas, or with manually pre-mixed air and gas.

The specifications:

Dimension: 1100mm x 145mm x 185mm,

Weight: 7.5kg / PC.

Heat output: 8500~16500 kcal/hr

LPG consumption: 0.8~1.5kg/hr

Inlet gas pressure: 1.2kpa for manually pre-mixed. 40~100kpa for naturally pre-mixed air and gas

Inlet air pressure: 2.8~3.5kpa, if needed.

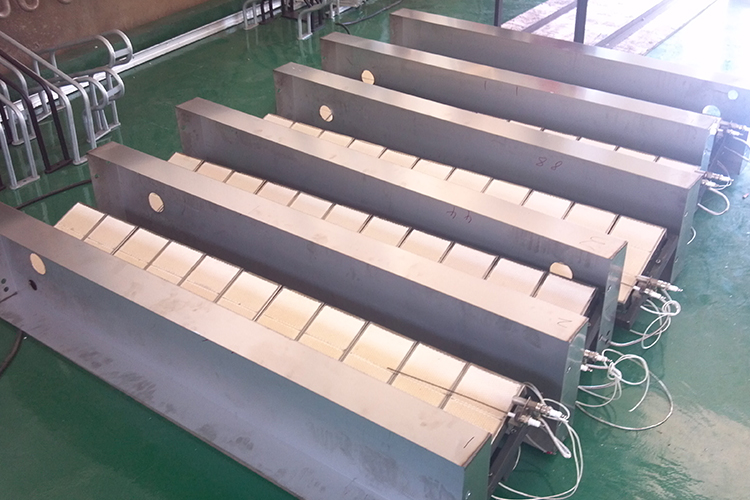

Work characteristics:

Safety: The 2.8 kPa low pressure natural ejector way premixed, more secure and reliable.

Efficient: Imported ceramic plate heat storage capacity, wide adjustment range, good radiation effects; its surface temperature may be in the range of 475 to 950 degrees Celsius adjusted to better carry out the coating operations.

Energy Saving: 1.63KW monolithic ceramic plate heating power, 0.12kg / hr monolithic ceramic plate ultra liquefied gas consumption.

Environmental protection: the entire system COX, NOx emissions below international standards related industries (in the standard system configuration and use of environment).

Wide range of applications: the option of using natural gas, liquefied petroleum gas, artificial gas and

Other gas.

Accurate control: drive, actuators and butterfly valves, furnace temperature throughout the system, PLC or OPTO22 central control module for precise control of the combustion.

Contact us if you need more details on

Infrared Burner. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Burner、Burner Infrared. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Radiant Burners > Metal Mesh Burners